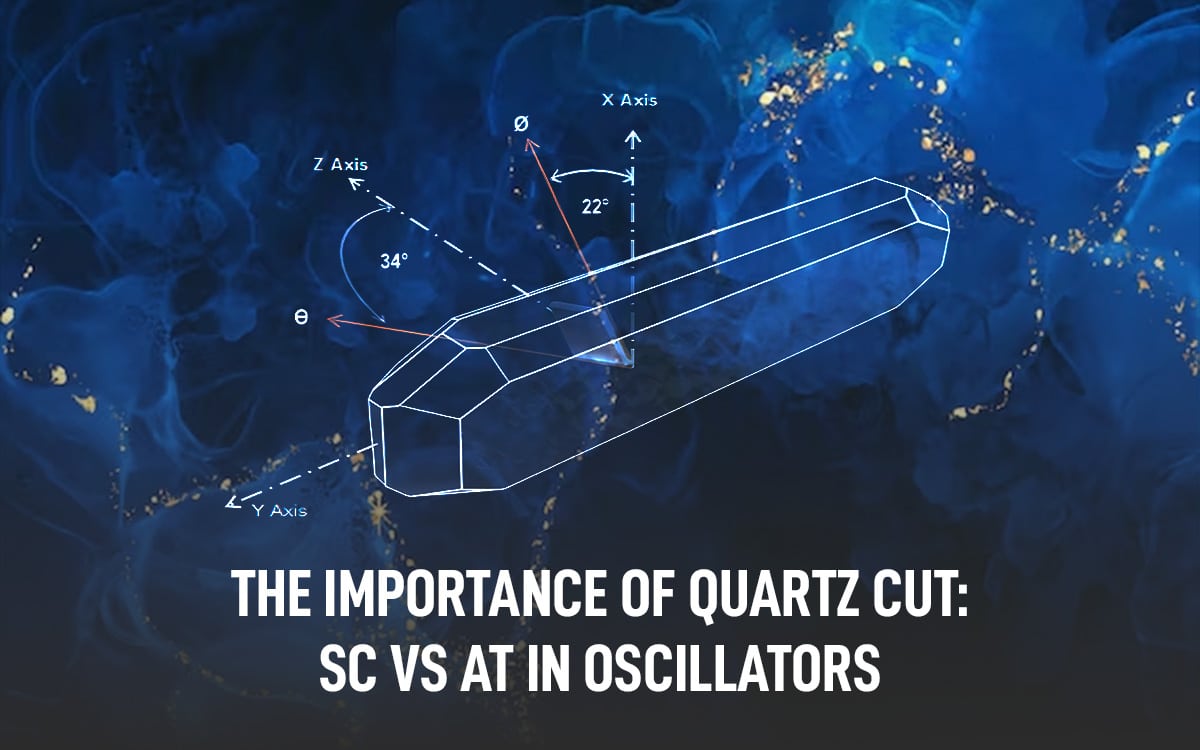

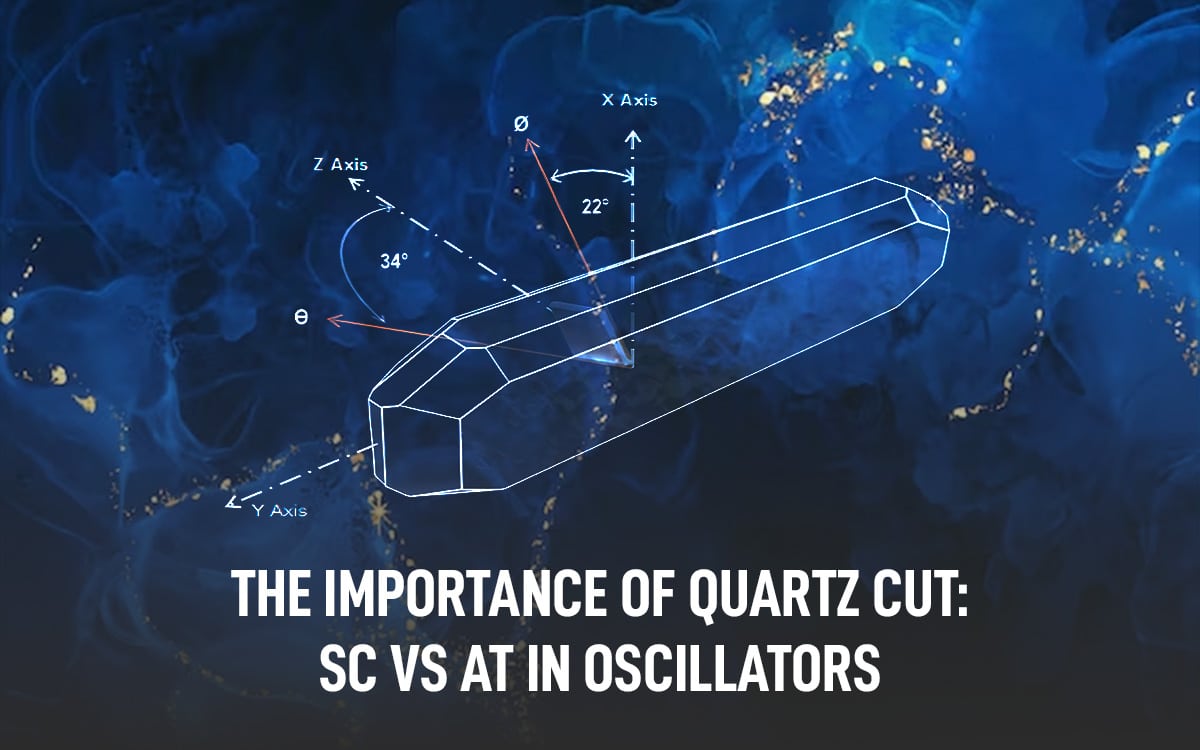

The Importance of Quartz Cut: SC vs AT in Oscillators

Oscillators are foundational elements in many electronic devices, from wristwatches to communication devices. At the heart of many of these oscillators lies a tiny, precisely cut piece of quartz crystal. The way this quartz is cut — specifically, the SC (Single-Crystal) or AT (Angle-Tuned) cut — plays a pivotal role in determining the performance and efficiency of the oscillator. Here’s a closer look at the importance of these quartz cuts and their relationship to the high Q factor.

1. The Cut of the Quartz: SC vs AT

- SC Cut (Single-Crystal Cut):

- The SC cut is designed to minimize frequency variations due to temperature changes. When temperature changes, an oscillator’s frequency can shift, causing inaccuracy in timekeeping or signal transmission. SC cut counters these variations, offering a more consistent output across a range of temperatures.

- AT Cut (Angle-Tuned Cut):

- Introduced in the 1930s, the AT cut is the most widely used cut in oscillator applications today. The angle at which the quartz is cut in relation to its crystallographic axis is crucial. The AT cut is made at an angle of approximately 35.25° to the crystal’s optical axis, which provides a balance between temperature stability and ease of manufacturing.

2. The High Q Factor: A Measure of Efficiency

- Understanding the Q Factor:

- The Q (quality) factor is a measure of how “resonant” a vibrating system is. In the context of quartz oscillators, it represents the crystal’s ability to resonate with minimal energy loss. A high Q factor means the crystal can sustain oscillations longer with less energy, leading to a more efficient and stable oscillator.

- Relationship with Quartz Cut:

- The cut of the quartz directly influences its Q factor. Properly cut quartz crystals, such as the SC or AT cuts, possess high Q factors. This is because these cuts optimize the crystal’s physical properties, minimizing energy losses due to mechanical and electrical damping.

- The SC cut typically exhibits a higher Q factor than the AT cut at room temperature. However, the Q factor for both cuts can vary depending on temperature and manufacturing quality.

Conclusion:

Quartz cuts — be it SC or AT — are more than just precise facets on a mineral. They are a testament to the sophistication of modern electronics and our understanding of material science. When matched with the high Q factor, these cuts ensure that our oscillators function with high efficiency, precision, and reliability, which are vital for the myriad of applications they serve in today’s world. Whether it’s keeping time or transmitting data, the role of quartz cut and its Q factor can’t be understated.